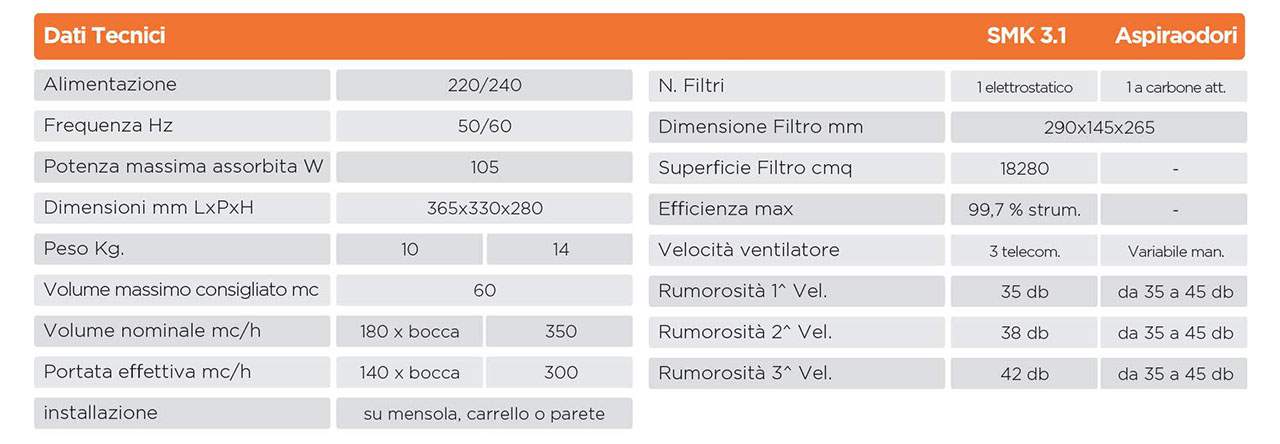

Description

SMK 3.1

The SMK 3.1 electronic purification system designed by COSDEP was developed on the basis of its own products and PATENTS, previously consolidated and long-proven. This equipment represents the ideal and irreplaceable solution for the elimination of fumes and dust in the workplace. In particular, the electrostatic filtering system, combined with the activated carbon filters at the purifier outlet, allows you to intervene directly where welding fumes, gases and processing dust originate.

PRINCIPLE OF OPERATION

1st PHASE: Aspiration of the dirty air by the centrifugal fan, electronically regulated and conveyed through the adjustable hood.

2nd PHASE: Electrostatic filtration: polluting particles up to 1 micron in size are ionized within the electrostatic field of the filter and retained by the negative blades.

3rd PHASE: Residual GAS filtration: the purified air is further filtered by a W-shaped activated carbon filter which retains the gases it contains. The clean air is then reintroduced into the environment at the same inlet temperature.

ASPIRATORS

The SMK gas purification system with activated carbon, designed by COSDEP, represents the ideal and irreplaceable solution for the elimination of gases and odors in the workplace. LSMK GAS mainly exploits the “ABSORBING” characteristic of the activated carbon filter it is equipped with. To fully exploit these characteristics, the filter is preceded by a metal pre-filter which has the purpose of filtering the air from dust. In this way, the air almost totally free of macroscopic impurities reaches the activated carbon filter, which would considerably shorten the “Average Life” of the activated carbon itself.

PRINCIPLE OF OPERATION

1st PHASE: Aspiration by the centrifugal motor, electronically regulated, conveyed through the adjustable hood.

2nd PHASE: The polluting particles in the air are partly filtered by the pre-filter and the air itself is definitively purified by 1 activated carbon filter which retains all the gases and odors the air contains. Please note: To have an optimal functioning of the 5 Kg. of activated carbon that make up the filter, the maximum speed of the air that passes through must not exceed 0.2 m/s, allowing excellent deodorization.

3rd PHASE: The definitively purified and deodorized air is reintroduced into the environment at the same entry temperature.

ADVANTAGES

Direct extraction of fumes, dust, gases and odors through the adjustable hood and self-supporting flexible pipe. Versatility of installation and flexibility of use, without hindering the workplace. Autonomous filtration without expulsion of the air outside and consequent heat loss. Maintenance of the electrostatic filter reduced to periodic manual washing without replacing any part and elimination of residual gases using an ACTIVATED CARBON filter.